What is the difference between paper cooling pads and plastic evaporative cooling pads?

Here’s a breakdown of the differences:

1. Material and structure

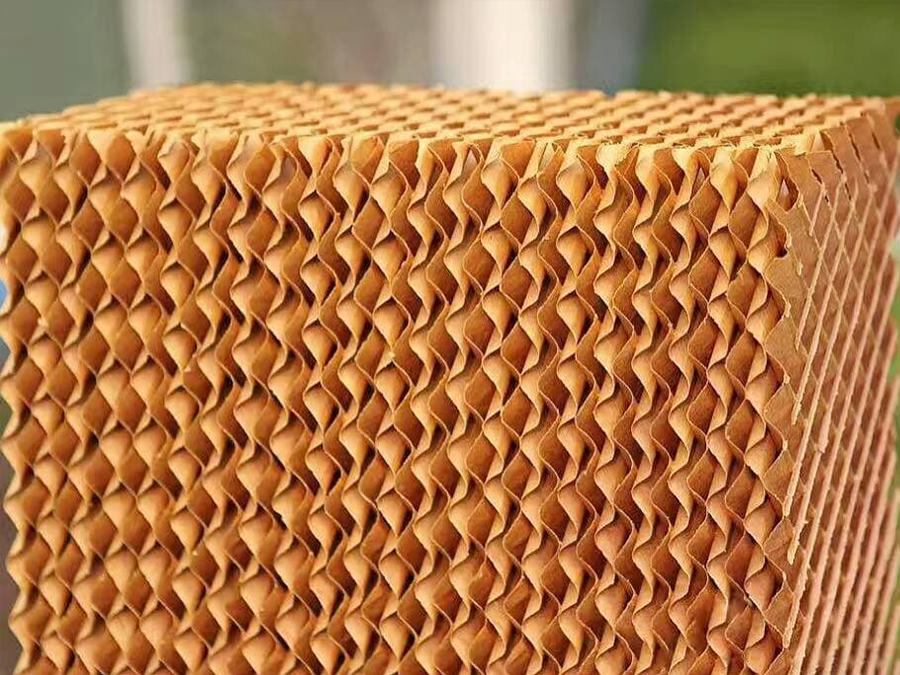

Paper cooling pad: It is made of raw paper processing and produced, with a honeycomb structure, usually with a wave height of 5mm, 7mm and 9mm three specifications, and the ripple is 60°×30° staggered opposition or 45°×45° staggered opposition. Its internal structural design helps to enhance water absorption and evaporation efficiency.

Plastic cooling pad: The plastic cooling pad is made of high-strength plastic material, which is specially treated to resist the damage of external factors such as ultraviolet light and chemical corrosion. The corrugations tend to be U-shaped and much larger than those found on traditional paper pads, which helps with the distribution of water and the passage of air.

2. Function and application

Paper cooling pad: The pad is mainly used for cooling pad system, through the water circulation system to make water flow through the surface of the cooling pad, when the outside air passes through, heat exchange with the water, so as to achieve the cooling effect. In addition, the paper cooling pad also has a certain filtering effect, which can remove some impurities in the air. It is widely used in poultry and animal husbandry, greenhouse and horticultural industries, and industrial cooling.

Plastic cooling pad: Plastic cooling pad has the same cooling function, but its unique material and design make it show more excellent performance in some aspects. For example, plastic cooling pads are more durable and easy to clean, resistant to ultraviolet light and chemical corrosion, reducing maintenance costs and efforts. At the same time, the plastic cooling pad also has a significant effect in deodorization, which can absorb and dissolve harmful gases in the air (such as ammonia), thereby improving the farming environment.

3. Performance characteristics

Paper cooling pad: has the characteristics of high water absorption, high evaporation efficiency, corrosion resistance, ventilation and so on. Its large internal surface area allows it to absorb and hold a relatively high amount of water, providing a long-lasting cooling effect.

Plastic cooling pad: Plastic cooling pad also has the characteristics of high cooling efficiency and strong durability. However, due to the particularity of its material and structure, the plastic cooling pad may be slightly inferior to the paper pad in water holding capacity. However, plastic cooling pads dry faster and are less likely to accumulate dirt and minerals, reducing cleaning and maintenance efforts.

4. Precautions for use

When choosing a paper cooling pad or a plastic cooling pad, it is necessary to make a comprehensive consideration according to the actual needs and farming environment. For example, plastic cooling pads may be more appropriate in situations where frequent cleaning and replacement of cooling pads are required; In the case of high requirements for cooling effect, paper cooling pad may be more advantageous.

During use, the cleanliness and wetness of the cooling pad should be checked regularly to ensure that it is working properly and performing to the best effect.