Paper Cooling Pads vs Plastic Evaporative Cooling Pads

1、Material composition

Paper cooling pad: usually made of plant fiber as the main raw material, through special processing technology, such as wood pulp, straw pulp and other fibers, through papermaking technology to form paper with a certain thickness and pore structure, some may add some chemical additives to enhance its performance, such as waterproofing agent, preservatives, etc.

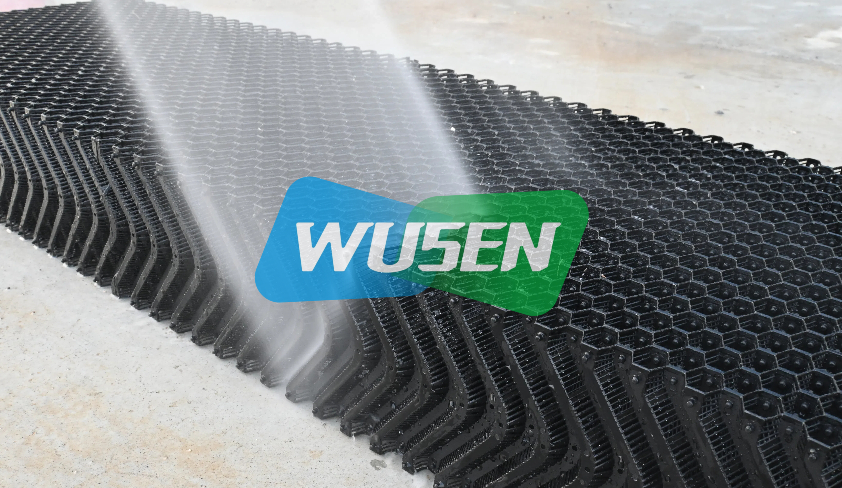

Plastic cooling pad: generally with high molecular polymer as the main component, common plastic materials such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), through extrusion, injection molding, molding and other molding processes, made into cooling pads with specific shapes and structures, may add some additives, such as anti-ultraviolet agents, flame retardants, etc.

2 、erformance characteristics

Water absorption and evaporation efficiency: paper cooling pads have strong water absorption, can quickly absorb water and take away heat through evaporation, and have higher evaporation efficiency in low humidity environments; plastic cooling pads have relatively weak water absorption, but some specially designed plastic cooling pads can also achieve better evaporation effects by increasing the surface area, etc., and their evaporation efficiency is relatively less affected in high humidity environments.

Air permeability: The fiber structure of the paper cooling pad makes it have good air permeability, and the air can pass through the cooling pad more smoothly, which helps to improve the cooling effect; the air permeability of the plastic cooling pad depends on its material and structural design. Some plastic cooling pads ensure a certain air permeability by designing special pores or channels, but overall it may be slightly inferior to the paper cooling pad.

Strength and durability: Paper cooling pads are relatively brittle and easily damaged by external forces. In long-term use or in a humid environment, the strength will decrease, and it is easy to break, deform, and other problems; plastic cooling pads have high strength and toughness, can withstand certain pressure and tension, are not easy to break, and have better durability in harsh environments.

3、Application scenarios

Agricultural field: Paper cooling pads are often used in small greenhouses, flower planting and other cost-sensitive scenes, which can provide plants with a suitable growth environment; plastic cooling pads are more suitable for large farms, agricultural factories and other places with complex environments and high durability requirements, which can effectively reduce the temperature of livestock and poultry houses and planting workshops.

Industrial field: Paper cooling pads are generally used in industrial cooling scenarios that do not have particularly strict requirements on humidity and pay more attention to cost control, such as some small processing workshops; plastic cooling pads are often used in industrial plants with high environmental requirements such as chemical and electronic industries due to their good corrosion resistance and durability, as well as in some cooling systems that require long-term stable operation.

4、Service life

Paper cooling pads: Under normal use conditions, the service life is usually short, generally 1-2 years. Frequent water absorption and drying processes may cause and drying processes may cause paper fiber damage, affecting its performance. In harsh environments such as humidity and high temperature, the service life may be shorter.

Plastic cooling pads: Under normal circumstances, the service life is long, up to 5-10 years or even longer. As long as it is not severely physically damaged or chemically corroded, the plastic cooling pad can maintain stable performance and provide long-term and effective support for the cooling system.

5、Maintenance

Paper cooling pads: Need to be replaced regularly to ensure the cooling effect. During use, pay attention to avoid moisture and mold, and keep it dry and ventilated during storage; if stains or damage are found after use, it is generally replaced directly, which is difficult to effectively clean and repair.

Plastic cooling pad: relatively easy to maintain, can be regularly rinsed with clean water to remove dust and impurities on the surface, can be cleaned with mild detergent when necessary, if local damage is found, in some cases, it can be repaired or some parts can be replaced.

6、Cost

Paper evaporative cooling pad: the raw material cost and production cost are relatively low, the initial investment is small, but due to the short service life, it needs to be replaced regularly, and the total cost of long-term use may not be low.

Plastic evaporative cooling pad: the production process is relatively complex, and the raw material cost is also high, so the initial purchase price is high, but because of its long service life and low maintenance cost, it has a good cost performance in the long run.