Quality Analysis of Plastic Evaporative Cooling Pads

(I) Characteristics of plastic raw materials

Plastic evaporative cooling pads are mainly made of plastic materials such as polypropylene (PP). High-quality plastic raw materials have excellent chemical stability and can effectively resist moisture erosion in humid environments and corrosion from various chemicals. For example, the use of UV-resistant materials can prevent rapid aging in light environments and extend the service life of the cooling pad. At the same time, the tightness of the molecular structure of the raw material determines its physical strength. The tight structure can enhance the toughness of the cooling pad, making it less likely to break in frequent water flow impact and air flow.

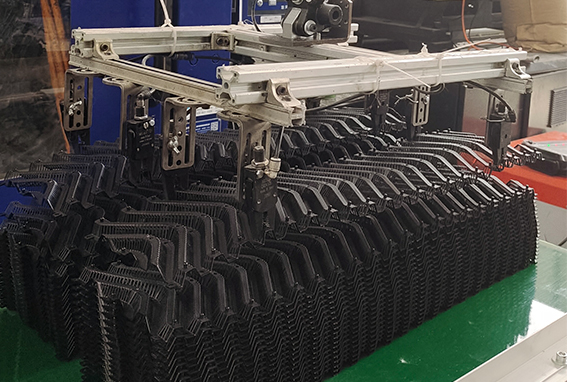

(II) Production process details

Advanced injection molding or extrusion processes have a significant impact on the quality of plastic evaporative cooling pads. During the injection molding process, precise control of temperature, pressure and injection time can ensure that the plastic fills the mold evenly, making the thickness of the cooling pad consistent and avoiding local over-thickness or over-thinness. The extrusion process requires a stable screw speed to ensure that the density of the extruded plastic profile is uniform and the internal pore distribution is reasonable. A reasonable molding process can also enhance the overall strength of the cooling pad. For example, the use of special hot pressing molding technology can make the bond between plastic molecules tighter and improve the durability of the cooling pad.

(III) Reasonable use of additives

In order to improve the performance of plastic evaporative cooling pads, a variety of functional additives are often added. Adding flame retardants can improve the fire safety of cooling pads, especially for industrial sites with high fire protection requirements; antistatic agents can reduce static electricity accumulation and avoid affecting the air permeability and evaporation efficiency of cooling pads due to static electricity adsorption of dust; in addition, adding antibacterial agents can inhibit the growth of microorganisms on the surface of cooling pads, maintain a good sanitary environment, and ensure indoor air quality.